Moulding and manufacture

The ear plug is custom moulded to each user.

It consists of the silicone earplug and the acoustic filter itself. Before beginning the manufacturing process, an examination has to be carried out to assess that it is safe to inject the moulding putty into the ear canal. During this examination, excess Cerumen (earwax) or Cerumen plugs should be removed from the ear canal.

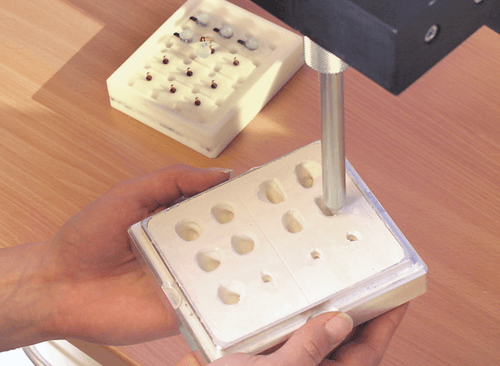

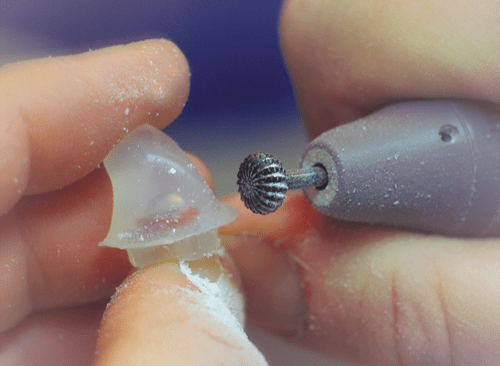

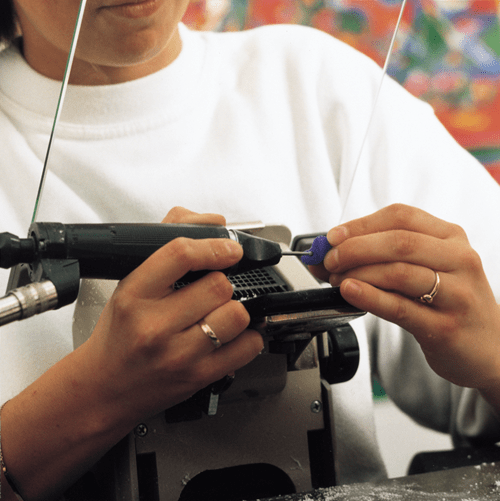

The moulding is performed according to current best practice for the fitting of hearing aids.The moulding material is a pliable two-component putty based on silicone. This is injected into the ear canal without any noticeable pressure. The moulding process is normally not uncomfortable. The result is a perfect copy of the ear canal and part of the Pinna. In the next production step, this mould is then used to form the final earpiece. This ensures it fits comfortably into the ear canal. A ventilation hole is drilled into the part that inserts into the ear canal and the appropriate acoustic filter is fitted, specifically tuned to your requirements for noise reduction.

Advantages of individual custom made Hearing protectors

- Customised for perfect fit

- Optimum protection

- Communication is retained

- Filters are individually chosen to suit the working environment.

- Important sounds and signals can still be heard• Ideal comfort, hardly noticeable

- High user acceptance

- Easy to wear with other items of PPE

- Easy to fit• Easy to clean

- Many applications. For example: metal industry, car manufacture, printing industry, cement works, food industry, chemical industry, woodworking industry, bottling plants and motor sports.