Unifocal and bifocal lenses

INFOR DUO

Bifocal lenses

For the simultaneous correction of difficulties in distance vision and the age related difficultie with near vision that occurs around the age of 40 onwards.

Visible transition between close and far lens sur-faces. In the case of age related vision difficulties there are blurry areas in the intermediate distance of approx. 40 cm to 1 meter.

Multifocal lenses

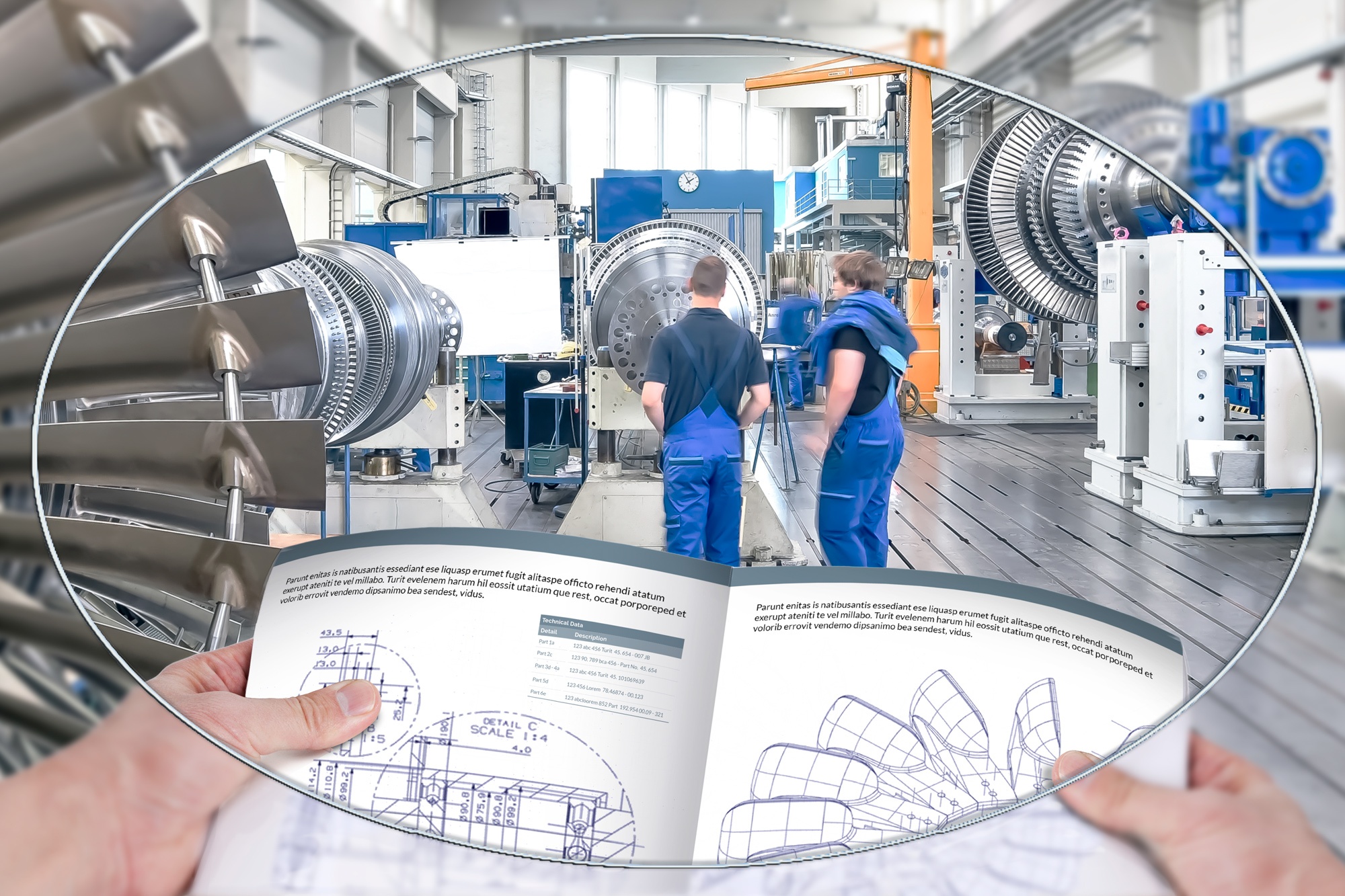

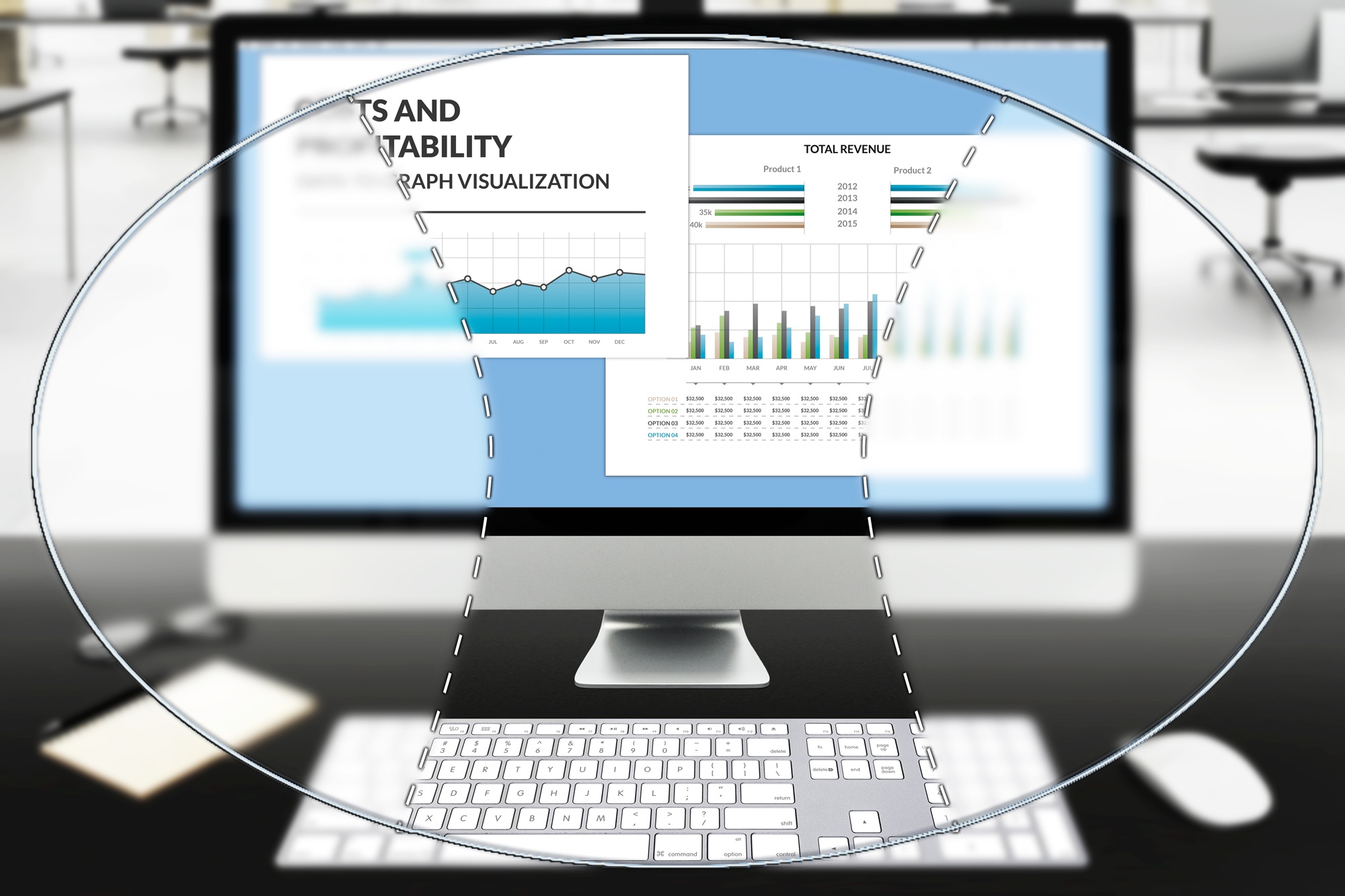

INFOR OFFICE

Office eyewear lenses

These seamless eyewear lenses can be precisely adjusted for any appropriate working distance. Such as your workplace PC screen, for example. The usable areas in the near and intermediate areas are larger than those of standard varifocal lenses.

This results in a comfortable head and body posture when performing tasks on a computer. The INFOR Officelens can be adjusted for distances of up to 4m. The lens is not approved for use when driving.

More comfort from personal computer eyeglasses with customised eyewear lenses

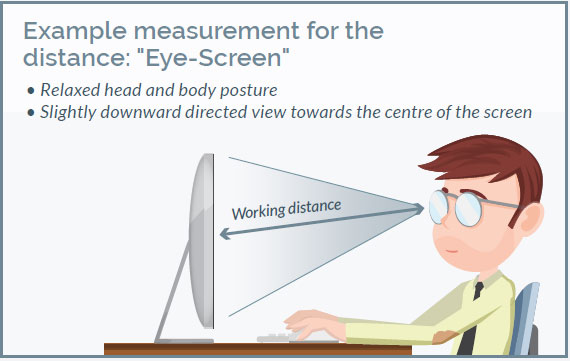

Eyewear with INFIELD Infor Officelenses are individually customised and adjusted to the exact centimetre for the working distance that is most often used. In addition, the desired distance should be measured in such a manner that the spectacle wearer is able to have a relaxed head and body posture at their workplace. The desired working distance should be between 40 cm and 1.5 m.

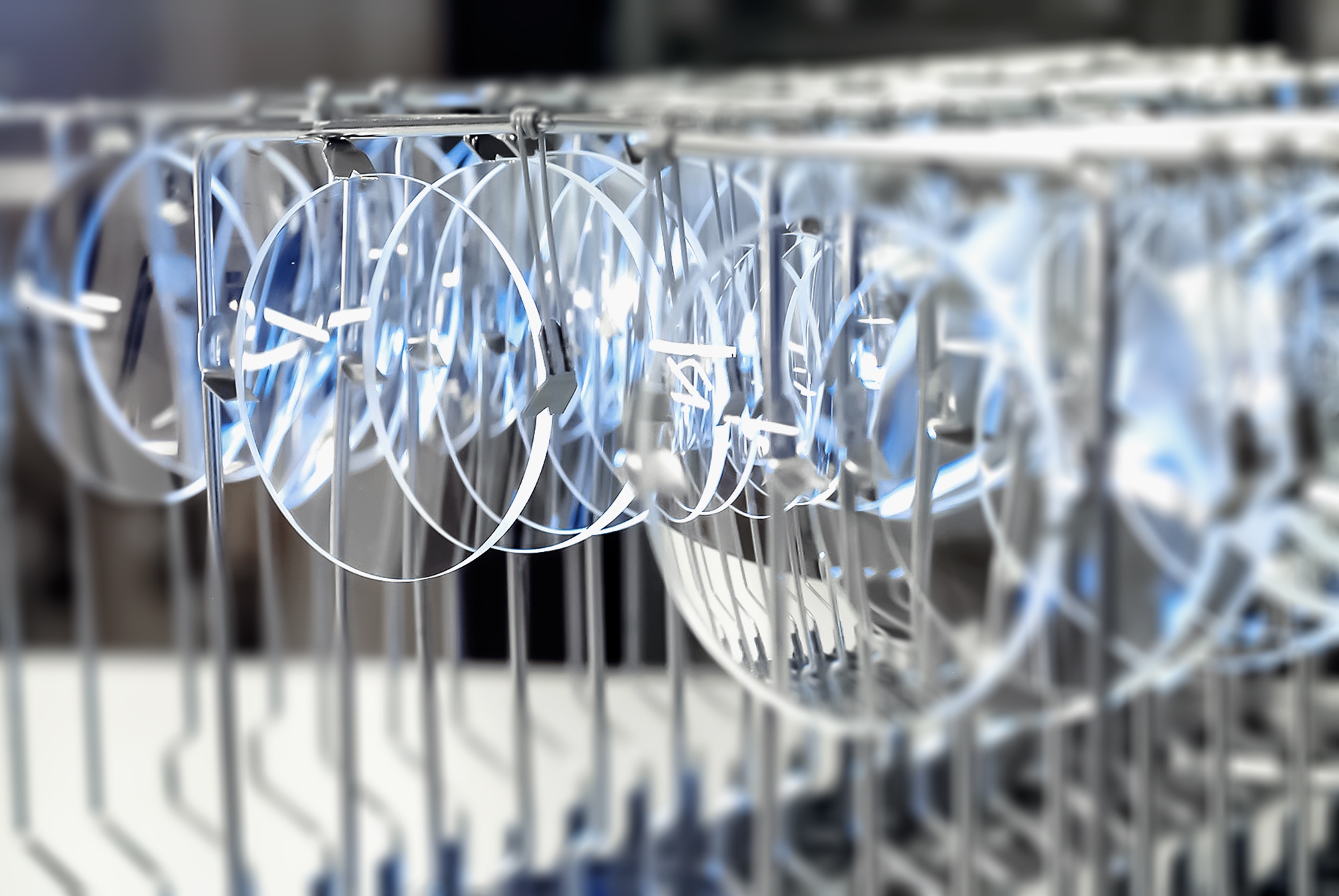

Digital manufacturing of eyewear lenses

The INFOR Freeform Technology

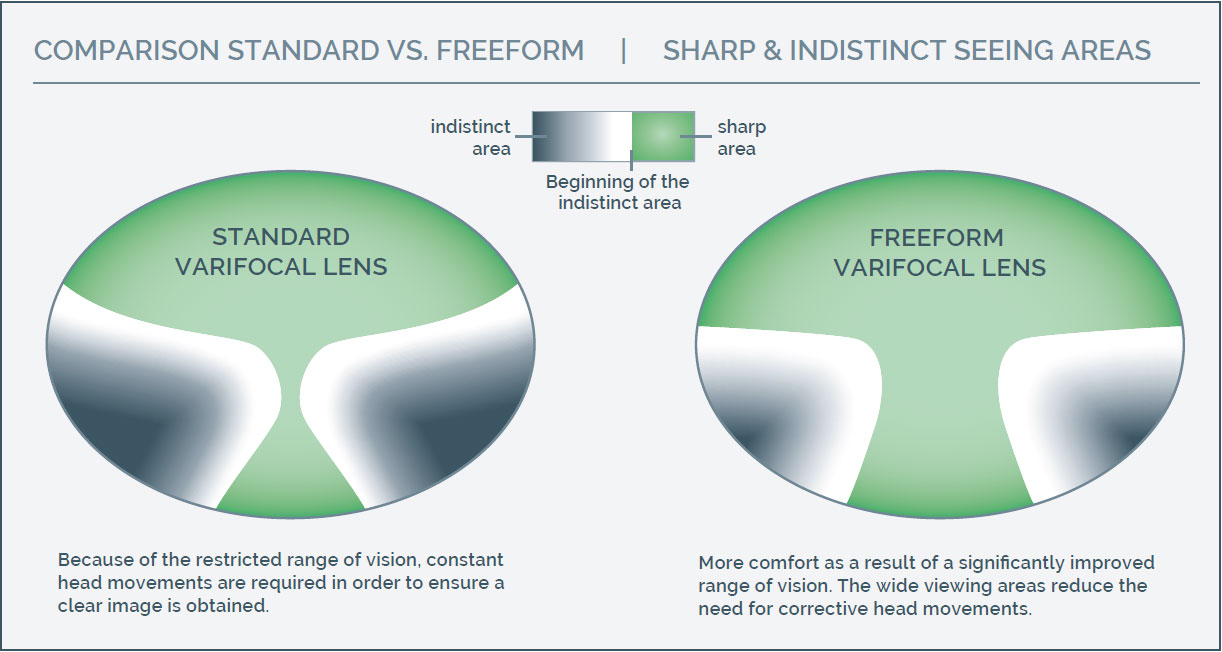

We have incorporated the latest lens production tech-nology – ‘Freeform’ – as standard in our INFOR multifocal lenses.

Conventional eyewear lens manufacturing is based on the processing of semi-finished basic lenses with tools in the form of segmented balls. This production method results in a relatively large area of the lens with blurry vision from the user’s perspective.

Only by utilising latest computerised manufacturing processes and high-end calculation programmes is it possible make the digital manufacturing of the freeform lenses possible. With this process, each point on the rear lens surface is individually calculated and formed, result-ing in a substantially improved image, compared to con-ventional varifocals.

Even in the case of freeform lenses, there are qualitative differences. Whereas some lens manufacturers only use standard programming for the calculation of the lens surface, INFIELD INFOR lenses are produced using a combination of multiple calculation programmes. Among them, our group’s very own Eyepoint Raytracing Programme. By means of the Eyepoint Raytracing Programme, we compute optical properties and simulate human vision from the perspective of the eye at almost 3000 points across the lens surface.

Benefits of the freeform technology

- It minimises the occurrence of image errors

- Peripheral vision comfort is improved

- No disturbing distortions

- Optimisation of the usable lens in near and inter-mediate areas, resulting in reduced head movements.

- The best possible lens design, matched to prescription, through modern technology

INFOR VARIO Varifocal lenses

Varifocal lenses – More and more customised

Optimised production processes for varifocal lenses however also have the consequence that it becomes increasingly difficult to switch between the lenses of various manufacturers. This is due to a certain “habituation effect” from the respective lens.

When it comes to safety eyewear for spectacle wearers, because of the nu-merous lenses offered on the market, it is not possible to take all these various lens designs into account. In ad-dition, it is not feasible to customise a lens 100 percent for a safety eyewear client. This is something which is more compatible for personal eyewear. For safety eyewear, the additional cost and time factor is not commensurate with the improved results.

INFIELD Safety has therefore developed a varifocal lens, in which the range of vision is created in a very special manner. Even more important, however, is the fact that the daily switching between personal and safety eyewear, is as comfortable and easy as possible for the wearer.

Lens materials and their characteristics

For each specification the right material solution

When it comes to safety eyewear for spectacle wearers selecting the right lens material depends on the user specifications,working environments, and specifictasks. INFIELD eyewear lenses are manufactured out of plastic material as well as mineral glass.

Eyewear lenses made of plastic material are especially good at protecting wearers from mechanical hazards and are finishedwith special coatings based on the individual working requirements of the wearer. In addition, plastic lenses are very light and can be very precisely adjusted to the specific vision requirements

Plastic material CR 39 – Index 1.5

Lens labelling: GA1SCE

Characteristics

- Lightweight

- Good chemical resistance

- Tint grades of 10% to 85% possible

- Resistant to spark burns during grinding and welding work

- Recommended for lens values of up to +/- 3 dioptre

Plastic material – High index 1.6

Lens labelling: GA1SCE

Characteristics

- Very low weight

- Good chemical resistance

- Very good scratch resistance through HC*

- 100% UV protection

- Recommended for high lens values in excess of +/- 3 dioptre

- Relatively thinner lenses even in the case of high lens values

- Resistant to spark burns during grinding and welding work

- Tint grades of 10% to 85% possible

Plastic material – High index 1.67

Lens labelling: GA1SCE

Characteristics

- Very lightweight

- Good chemical resistance

- Very good scratch resistance through HC*

- 100% UV protection

- Recommended for high lens values in excess of +/- 6 dioptre

- Relatively thinner lenses even in the case of high lens values

- Resistant to spark burns during grinding and welding work

- Tint grades of 10% to 85% possible

Polycarbonate – Index 1.59

Lens labelling: GA1SCE

Characteristics

- Lightweight

- Very high mechanical impact strength

- 100% UV protection

- Tint grades of up to 15% possible

- Available for all lens values

- Increased scratch resistance through surface coatings

- Resistant to spark burns during grinding and welding work

Trivex Index 1,53

Lens labelling: GA1SCE

Characteristics

- Lightweight

- Good chemical resistance

- 100% UV protection

- Ideal optical characteristics

- Available for all lens values

- Tint grades of up to 15% possible

Tempered glass – High index 1.6

Lens labelling: GA1SCE

Characteristics

- Very high scratch resistant properties

- Good chemical resistance

- Less resistance to spark burns during grinding and welding work

- Available for all lens values

Mineral glass

For working areas containing abrasive dust, we recommended eyewear lenses made of mineral glass, because this material has the highest scratch resistant properties.

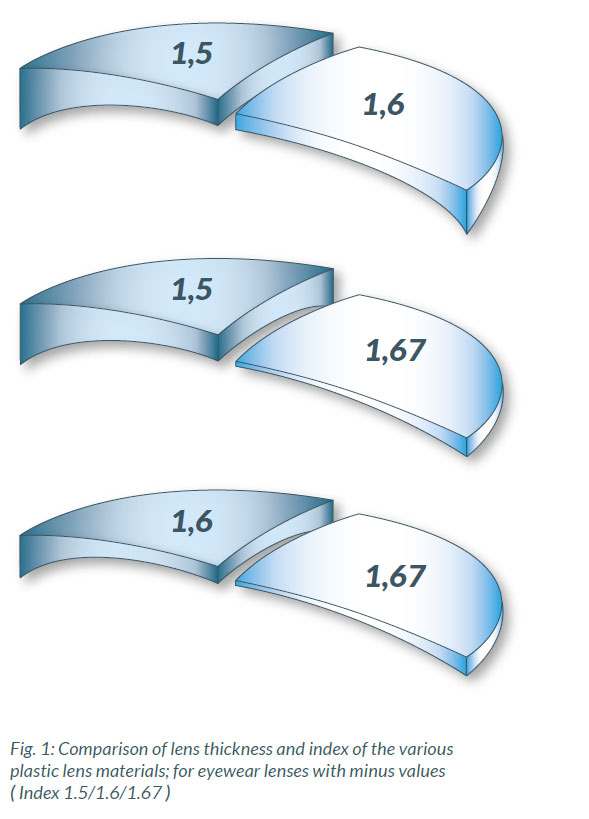

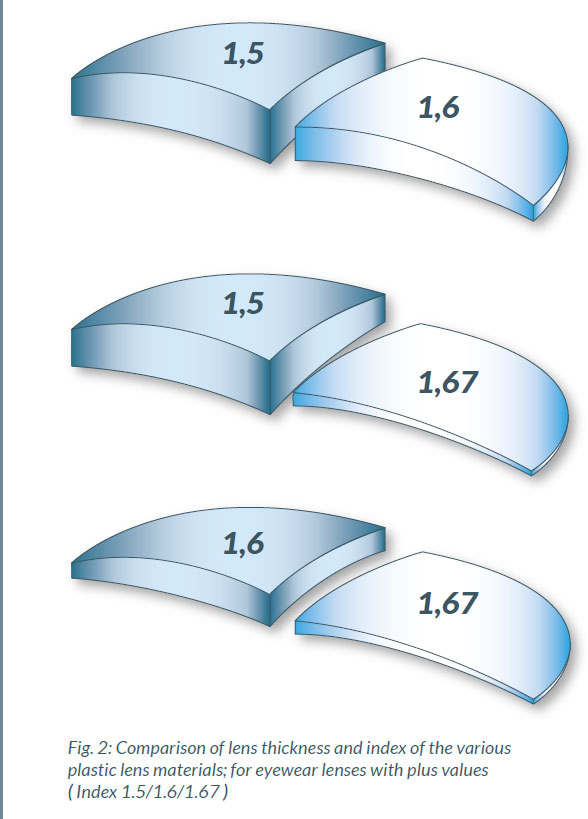

Plastic lens material – High index

High index – higher index materials

Eyewear lenses get increasingly thicker either at the edge or in the centre. From approx. +/- 3 dioptres, we recommend using high index materials. Because of an increased optical density, such materials have a higher refractive power, compared to conventional eyewear lenses. They can therefore, be manufactured with thin-ner edge or centre thickness. In addition to cosmetic advantages, the weight can be reduced by up to 30%. The higher the refractive power (see Fig. 1&2), the thinner the eyewear lenses can be made.

Coating technology – ProCoat

ProCoat – The optimal protection for all working conditions

Our coating technology has developed from many years of experience in the development of products for occupational safety / personal protection equipment. Our problem-specific solutions for very hazardous situation.

ProCoat HC – super scratch resistant

With this thin coating on the lens surface, the lens receives especially high scratch resistance properties. It is protected against environmental influences and resistant to wear. It is also easy to clean and maintain. In addition, the hard coat-ing improves the protection against chemical influences.

| ProCoat | Coating(s): | Hard Coating | |

| HC | Description (Abbr.): | HC |

ProCoat SAR – Anti reflection coating

A mirror reflects up to a 96% of light. That is why we can see ourselves in it. Eyewear lenses (even though they are transparent and clear) still reflect approx. 8% of the light that hits them. This results in unpleasant reflections on the rear surface of the lens, causing vision irritations. In addition, the light transmission is restricted due to the reflection on the front lens surface. Anti-reflective coatings on eyewear lenses increase the light transmission by up to 99%. Visual discomfort from light being reflected into the yes is almost completely eliminated.

| ProCoat | Coating(s): | Super Anti Reflex | ||

| SAR | Description (Abbr.): | SAR |

ProCoat OSC – Multi coating (hard coat + anti reflection oat + clean efect)

In addition to anti-reflective properties, this coating also offers extraordinarily high scratch resistant properties and a cleaning effect. OSC-coated eyewear lenses are especially well protected against low and high viscosity substances, along with other particle and environmental influences. Thy are very easy to clean and care for.

| ProCoat | Coating(s): | Super Anti Reflex | Hard Coating | Clean Code | |

| OSC | Description (Abbr.): | SAR | HC | CC |

ProCoat OptiFog – Multi coating (hard coat + anti reflection oat + anti-fog)

The eyewear lens receives a highly effective anti-fog finish,in addition to an anti-reflectioncoat and hard coat. Lenses with this coating are therefore especially suitable for working environments with diffuse lighting conditions and frequent changes in temperature / humidity. When necessary, the anti-fog coat is reactivated by means of the OptiFog Activator eyewear cloth.

| ProCoat | Coating(s): | Super Anti Reflex | Hard Coating | OptiFrog | |

| OptiFog | Description: | SAR | HC | AF |

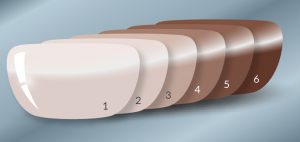

Permanent tints

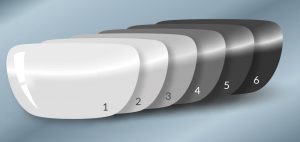

Colour scheme and tint grades

If tinted eyewear lenses are required, the colours brown and grey can be selected in various tint grades. The se-lection of the tint colour is primarily a matter of individual taste and also dependent on the colour of the eyewear frame. Various tint grades enable the wearer to customise the lens to their requirements.

| Brown tints | Level | Intensity | ||

|---|---|---|---|---|

| Protection from natural glare |  | 1/2 | 10 & 15% (weak) |

|

| Various tint grades | 3/4 | 30 & 60% (middle) |

||

| Increased contrast | 5/6 | 75 & 85% (strong) |

||

| Warmer, more pleasant visual impression | ||||

| Grey tints | Level | Intensity | ||

|---|---|---|---|---|

| Protection from natural glare |  | 1/2 | 10 & 15% (weak) |

|

| Various tint grades | 3/4 | 30 & 60% (medium) |

||

| Ideal for light sensitivity, because grey is subjectively perceived as darker | 5/6 | 75 & 85% (strong) |

||

Weak tint of 10 and 15%

This tint grade can be worn throughout the entire day, as well as when driving a car at night. Because of the low level of the tint this can prevent eye fatigue and headaches. Due to the lightness of the shade, this tint only offers minimal glare protection.

Medium tint of 30 and 60%

This tint grade offers protection from more severe light sensitivity. This degree of tint should not be used when driving at night.

Strong tint of 75 and 85%

This tint grade offers perfect glare protection from the sun’s rays. Classic sun protection lenses are made with a tint of at least 75%. They are also not suitable for night driving.

Variable tints

Photochromic eyewear lenses – self tinting from 7 to 85%

Photochromic eyewear lenses have molecules that react to UV radiation. The lenses automatically darken as the level of UV increases. This self-tinting ensures an optimal adjustment to changing light conditions. The wearer longer needs to switch between normal eyewear and sunglasses. Photochromic eyewear lenses have a base tint of 7% and available in grey or brown tint.

Tint strength approx. 75-85%

In the case of bright sunshine, UV radiation is at its highest and the eyes require intensive sun protection. The eyewear lenses darken up to the maximum tint.

Medium to strong tintapprox. 30-60%

In partly cloudy conditions with sunny intervals, there is always an increase in UV radiation. The eyewear lenses in this case darken to a medium to strong extent, depending on how the clouds and sunny periods are distributed.

Weak to medium tint approx. 10-30%

In the case of cloudy weather and diffused light, the UV exposure is minimal. The eyewear lenses darken only minimally.

Weak base tintapprox. 7%

There is no UV radiation. Perhaps in the case of very cloudy conditions, in the dark, or when performing tasks indoors.